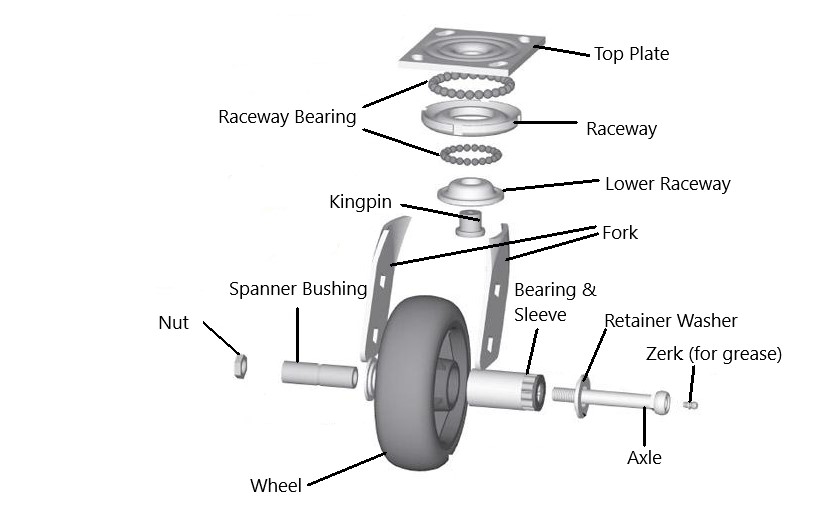

Parts of a Caster

Not every caster will look like the one above, but this is a very common assembly.

- Top Plate: Also referred to as the "fastener", is how the caster will attach to the item. (other options include threaded stems, grip-ring stems, and expandable adapter stems.

- The raceway is what makes a swivel caster, swivel. Some will have a single ball raceway while others will have a double ball raceway like shown above. Double ball raceways are stronger and allow for easier movement.

- The kingpin is what holds the raceway together on a swivel caster. For some extreme duty applications we will recommend using a "kingpinless" design. Like found in our WC 9400 SERIES, WC 9500 SERIES, and a few others.

- The forks are the "legs" that hold the wheel.

- The other components will be varied based on your Application and Environment. I.E.; a caster designed to be used in wet environment will, in most cases, not want a steel roller bearing(as they will rust). While a bearing may be needed for heavier Applications.

- Wheel Material and Size are also something that will vary based on Application and Environment. I.E.; A hard wheel will roll on smooth floors very well, but will more easily get hung up on cracks and debris. Also you would not want to use a Polyolefin Wheel for a high temperature application.